As the semiconductor field moves to better nodes, mixed integration, and fast applications, the work of main equipment parts has turned into a key point for making efficiency and product success. From front-end wafer work to back-end packing and checks, each tiny shift in part action can affect cost, work level, and output speed.

In this setting, picking semiconductor equipment main parts based on exact technical details is not an option. It is a must. This piece looks at the main needs you should think about for different key parts. It also shows how fitting these to your steps leads to the best making results.

For people looking for a reliable helper in exact part building, DEEPETCH gives a full set of answers. As a tech company in Shenzhen started in 2019, DEEPETCH has grown into a tech firm that mixes research, building, making, and selling. Its skills cover power semiconductors, sensors, analog ICs, and others.

Crucial Role of Technical Parameters in Semiconductor Equipment Core Components

The semiconductor equipment field is changing fast. It faces pushes from smaller sizes, more power in small spaces, and harder mixing. This change asks that each main part hits tough technical limits for rightness, heat steadiness, and trust.

Semiconductor raw stuff is a needed part in finishing the semiconductor chain. It helps every step in making semiconductor chips. But it is not just the raw stuff. It is also the built parts. Things like chucks, ion grids, and quartz plates directly touch success rates and work exactness.

This piece will aid you in lining up technical needs with equipment wants. It also brings in DEEPETCH as a special seller of made-to-order semiconductor equipment parts. They offer full steps from building to after-sell help.

Key Technical Parameter Requirements for Major Semiconductor Equipment Core Components

Choosing the best main parts rests on knowing each one’s job role and work measures. Here is a simple split by kind:

Wafer Tray

Wafer trays are critical carriers for safely transporting and precisely positioning wafers between processes, especially in PSS nano-imprint lithography for LED sapphire substrates.

- Material Requirements High-strength aerospace-grade aluminum alloy (6061/7075) is used as the base material, with hard anodizing or special coating on the surface.

- Dimensional & Flatness Precision Overall flatness of the tray is controlled within ≤10 μm, pocket depth consistency ≤5 μm, and pocket sidewall verticality ≤0.01 mm. This ensures that every 4-inch or 6-inch wafer is placed at exactly the same height and position, achieving sub-micron overlay accuracy in nano-imprint equipment (Maxis/NMC).

- Pocket Position & Spacing Uniformity The relative position accuracy of each wafer pocket is ≤20 μm (typically reaching 8–12 μm), and the spacing between pockets is strictly consistent. This prevents wafer shift or collision during high-speed robotic handling and multiple transfers, significantly reducing wafer breakage and chipping rates.

Ion Source Grids

Ion source grids right away shape ion planting quality.

- Material Performance: These grids work in very hard spots. They need heat fight (≥1000℃) and stand against ion hits (molybdenum, tungsten mixes). This keeps them lasting and working well.

- Aperture Precision: Tiny control over hole size and space sets beam shape truth.

- Electrical Properties: Good flow of power and stand against volts are main for steady beam flow send.

- DEEPETCH gives made ion source grid sets for ion implanters. Their work life is 30% longer than the usual. You can see product details at chips in stock.

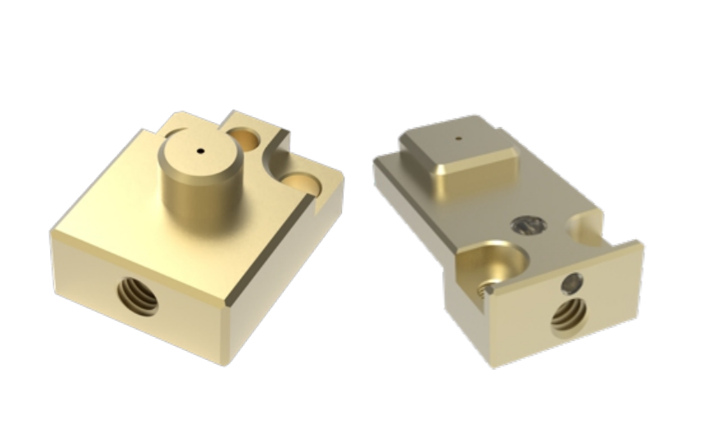

图片: Ion Source Grids

Quartz Plates/Cover Plates

Quartz is a must in light and heat steps.

- Purity: Clean need: SiO2 amount ≥99.999%. Low bad stuff to stop wafer dirt.

- Transmittance: Must be ≥90% for UV and see light. This is key in photolithography.

- Thermal Stability: Low heat grow (≤0.5×10^-6/℃) stops bend in quick heat changes.

Chip Stages

Chip stages must let exact moves and steadiness under changing weights.

- Positioning Accuracy: Tiny-level rightness (±5nm) is needed for line-up in better lithography.

- Load Capacity & Stability: Holds different chip types without losing balance.

- Vibration Dampening: Cuts shake noise to keep very tiny rightness.

How to Select Core Components Based on Technical Parameters?

To make output lines better, your pick must fit both step-by-step needs and wider field marks:

- Match with Process Type: If you work with lithography or ion planting, each step has its own heat, light, or move limits.

- Component Compatibility & Durability: Make sure stuff fits with gases or chemicals in making. Think about wear turns in real spots.

- Reference Standards: Always line up details with SEMI or ISO marks for trust check.

- For a made fit, DEEPETCH gives one-stop made service for main parts. Their skilled teams check your steps to match technical details just right.

Why Choose DEEPETCH for Semiconductor Equipment Core Components?

When you work with DEEPETCH, you get more than just pieces. You reach a full building system:

- Good research power: skilled research team on semiconductor part tech for over 10 years.

- Tight quality watch: follow ISO 9001 and SEMI marks, 100% test before send.

- Made service: give personal answers based on customer technical detail needs.

- World after-sell help: quick answer and on-site tech aid.

Conclusion

The work of semiconductor equipment ties close to the technical details of its main parts. This goes from even heat to tiny placing. Picking parts that hit these tough details makes sure step steadiness and making success. Working with partners like DEEPETCH can raise your making skills a lot. They give building-to-send made work backed by field papers.

FAQ

Q1: How do I determine which technical parameters are most critical for my application?

A: Begin by mapping your process flow (e.g., lithography, etching) to the job needs of each part. Then check SEMI marks. Work with sellers like DEEPETCH who give detail-match help.

Q2: Why is aperture precision important in ion source grids?

A: It makes sure the ion beam shape stays steady in planting. This touches dose evenness and device work.

Q3: Can DEEPETCH support custom sample development before mass production?

A: Yes. Their made process has sample making, testing, feedback get, and last check before big making.

Q4: Are DEEPETCH’s products compliant with global quality standards?

A: Yes. They use ISO9001 watch systems. Plus, 100% test on all send products to make sure trust.